The history of the Diesel engine dates back to 19th century. Since then its construction didn’t change much. Of course, modern motors are using electronic sensors and their work is monitored by computers but overall working principle remains the same.

How does the Diesel unit work? How is it built? What are the benefits of Diesel Dual fuel system? You will learn all these things from the following article.

1. Brief history of the compression-ignition engine

German engineer Rudolf Alexander Diesel is considered to be the father of the compression-ignition engine. His main goal was to create a self-ignition motor that is more efficient than standard petrol units. The inventor spent years experimenting with compression-ignition motor build, powered with many different types of fuel. He started with creating the unit powered with coal dust. Unfortunately, this substance has high abrasive properties that makes it impractical for the metal engine. Throughout the years engineer tried several kinds of fuel, but in the end he chose oil.

Persistent work paid off and in 1893 Rudolf Diesel received a patent for the compression-ignition engine. The invention worked well in many kinds of machines, such as trucks, agricultural machinery, electric generators or locomotives. The first truck with compression ignition engine was presented in 1923 by Benz & Cie company.

Źródło: https://www.sabo.it/en/the-worlds-first-ever-diesel-trucks-from-benz-and-daimler-in-1923/

Over the time the compression-ignition engines began to be equipped in passenger cars. The pioneer vehicles in this category were Citroën Rosalie and Mercedes-Benz 260 D, which went to the market in the early 1930s.

2. Construction of the Diesel engine

The Diesel engine – also called compression-ignition or oil engine – doesn’t need a spark to ignite the mixture of fuel and air. This is what makes it different from petrol motors.

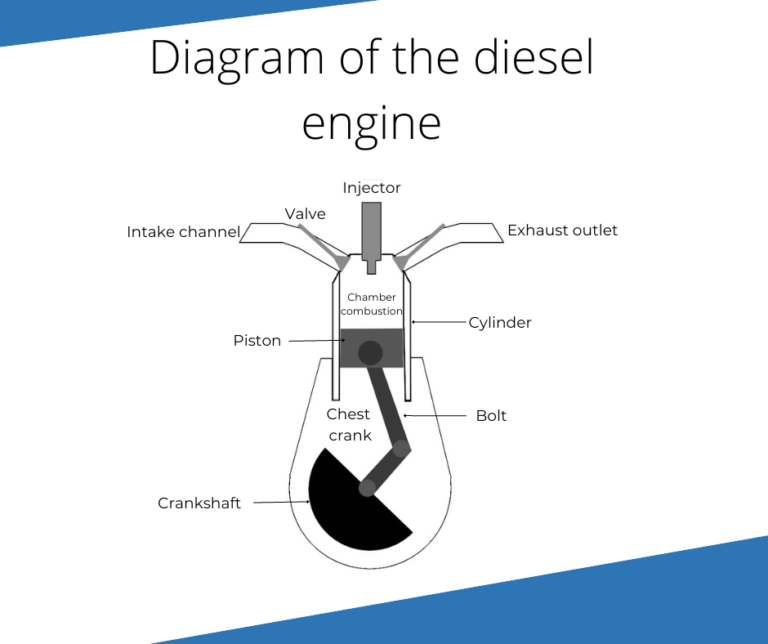

The central part of the unit is its body. Its structure is entirely cast in metal and has round holes – cylinders. At the top of it there is a cylinder head. The space between body and the cylinder head is called the combustion chamber. Inside of it there are:

– an intake channel and an exhaust outlet,

– valves controlling air supply and exhaust gas removal,

– fuel injectors.

Inside of the cylinders there are moving pistons. Their movement causes air to enter the combustion chamber, where it is compressed until the mixture ignites. The level of the compression is in the range of 12-23:1. Compressed air increases its temperature to 700-900 C. When oil gets into the combustion chamber, mixture ignites. Energy of the explosion is transferred to the crankshaft and conveyed out of the engine.

When describing the elements of the compression-ignition motor, you can’t forget about glow plugs. They are the silent heroes, which make the machine start even in the cold days. Their job is to heat up the air going to the combustion chamber. Cold installation, without working glow plugs, could have problems with bringing the air to the right temperature and triggering self-ignition.

3. The Diesel engine – how does it work?

The compression-ignition engine has a four-stroke cycle. To really understand how it works, you need to know what is the stroke. It is one movement of the piston – upside or downside. The full cycle of the motor consists four movements – downside, upside, downside and upside.

The first piston movement enlarges the space of the combustion chamber. The underpressure draws in air through the open valve. Then the piston moves up, compressing the air and increasing its temperature. Motor oil gets injected. The resulting mixture ignites and an explosion occurs. It pushes the piston with great force and creates kinetic energy, causing the crankshaft to rotate. When the piston returns up, it removes the exhaust gases from the chamber. The return is possible not only due to the inertia force, but also with the help of other pistons at a different point in the cycle. That is why engine with more cylinders works smoother.

4. Are diesel powered vehicles popular?

Person who doesn’t know how many cars use the compression-ignition motor, may think that diesel engines are mainly the domain of trucks, industrial machines or special vehicles. Obviously, there is a lot of the truth in this statement, but you can’t ignore passenger cars using this technology. In total, over 40% vehicles on the roads are powered by a diesel.

No wonder, this type of vehicles is known for a very good reputation among many drivers. They are valued for their durability – many diesel motors are able to drive over 400,000 kilometres. Some of the drivers choose them for the high torque and very good dynamics, even at relatively low RPM.

5. Diesel with the Dual fuel system

The compression-ignition engine is a proven design, which hardly changed since the time it was invented. So, is there any space for improvement here? Of course!

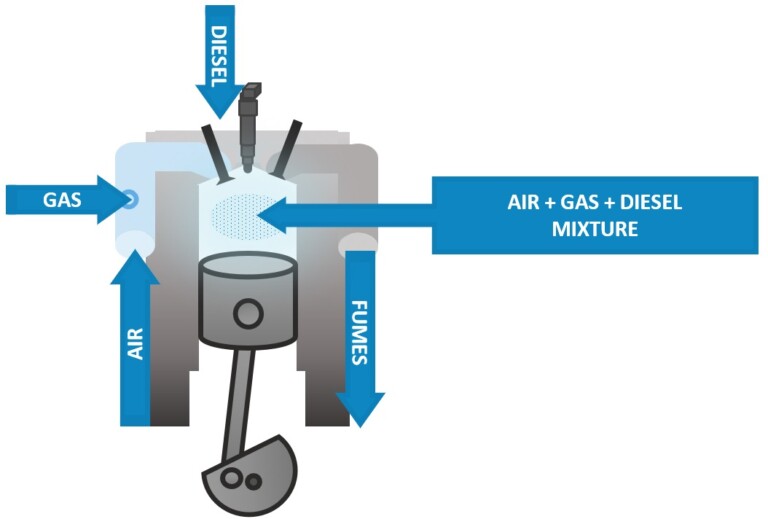

You can make a modification which let you use the alternative fuel that will replace diesel. However, it should be remembered that, unlike gasoline motors, diesel units cannot use gas as the only fuel. Explosion of the air and gas would be too unpredictable in compression-ignition engines and it would lead to knocking combustion. In that case, the solution is to use two types of fuel at a time. As a result, a mixture of diesel, gas (LPG, CNG or LNG) and air is created in the chamber. It works really well in the compression-ignition engine.

5.1 What are the benefits of dual fuel system of compression-ignition engines?

The usage of two types of fuel allows partial replacement of diesel with gas. This is an opportunity to achieve significant savings. Gas costs about half as the price of diesel. When using system with LPG, if 20 to 25% oil is replaced with gas, it will result in significant savings. For the CNG installation, the level of replacement is much higher and reaches even 50%.

Moreover the mixture of gas, oil and air burns in higher temperature, which would significantly increase vehicle’s power and torque.

Many people wonder – how much savings does the diesel to gas conversion bring? Does it generate them at all? For the Fuel Fusion installation, this can be calculated. Our DDF installation stands out from the competition, because it gives access to precise and reliable data. The controller generates logs related to the work of the vehicle and saves them in its memory. These can be downloaded using a USB cable to the hard drive and be uploaded to our website to create statistics. Using that way you can get information like:

– overall gas and oil consumption,

– both fuels consumption in Dual fuel mode on,

– the distance travelled in Diesel and Dual fuel mode,

– percentage of the distance travelled with exhausted gas,

– percentage share of the road travelled with the Dual fuel installation switched off by the system or manually by the driver.

For the most of DDF installations available on the market, savings can be only calculated by comparing the bills from before the installation of the Dual power supply system with later ones. Unfortunately this method won’t give precise results. The situation is different when it comes to Fuel Fusion system. The data contained in the reports allow much more precise calculation of the level of savings. It also gives you an overview of other parameters of the installation and show for example possible system errors or manual switch off of the installation by the driver.

The Dual fuel installation also gives benefits related to the vehicle’s impact on the environment. A mixture enriched with gas burns in a higher temperature. Thanks to this fact the harmful components of the smoke are burnt out instead of being emitted to the atmosphere. The reduction of solid particles emissions, mainly responsible for the formation of smog, drops by as much as 60 to 70%. For vehicles that meet the EURO 6 standards – which is currently the most demanding EU standard in terms of exhaust emissions – the system is able to reduce CO2 emissions by an additional 4.5%.

5.2 Fuel Fusion – gas installation in compression-ignition engines

Fuel Fusion is our company’s diesel dual fuel system. The brain of the whole installation is the controller (ECU). It controls all parts of the gas installation and gathers data related to its operation. Inside the driver’s cabin – in the easily reachable place – there is a switch. It allows the gas system to be turned on or off while driving. The switch is equipped with the diodes that inform about estimated amount of gas in the tank.

Installation of Fuel Fusion system doesn’t cause major changes inside the combustion system. The gas enters the engine with the air, so there is no need to interfere with the construction of the combustion chamber. The proper and safe gas supply is provided by:

– gas injectors,

– pressure sensor in the intake manifold,

– gas pressure reducer,

– gas filter.

The Dual fuel installation can’t work without components related to gas refuelling and storage. These include the filling valve, gas tank or brackets for mounting tanks.

The safety of the engine is ensured by the EGT (Exhaust Gas Temperature) probe. If the temperature is rising, it means that something disturbing is most likely going on inside the cylinders. In such a situation the system automatically reduces the amount of gas injected or cuts it off completely.

Do you want to know more about the specifics of the Fuel Fusion system? Read about it here.