Every gas installation is working on data, that reflects the work of the machine and fuel. Thanks to them, the gas controller can adjust the operation of the entire system to a certain situation. The most important information includes gas pressure, manifold pressure and gas temperature. We obtain them using the MAP sensor. The name of this component is a partial acronym that can be expanded to Manifold Absolute Pressure Sensor.

How does the MAP sensor work?

The MAP sensor monitors the current gas flow, informing the gas installation controller about any irregularities. Thanks to it, you can be sure that the gas pressure is neither too high nor too low.

Before the gas reaches the injectors, it passes through the reducer. At this stage, its pressure is reduced and the temperature increases. This stage is crucial for the safety of the entire installation. Too high pressure could damage the hose connections, injectors and other elements. Too low temperature could cause the system’s elements freeze, which would significantly affect the lifespan of the installation elements.

In addition, the MAP sensor supports the operation of gas injectors and allows to avoid situations in which the gas doses are not equal, which could lead to RPMs fluctuations and to loss of the engine power.

Checking these parameters is therefore necessary. The MAP sensor is used for this purpose. It acts as a sensor that measures the pressure and the temperature of the flowing gas. It works on data obtained in real time. If an irregularity is detected, it can quickly send a signal to the controller, which will react, for example, by changing the installation’s operating mode to Diesel Mode.

Connection

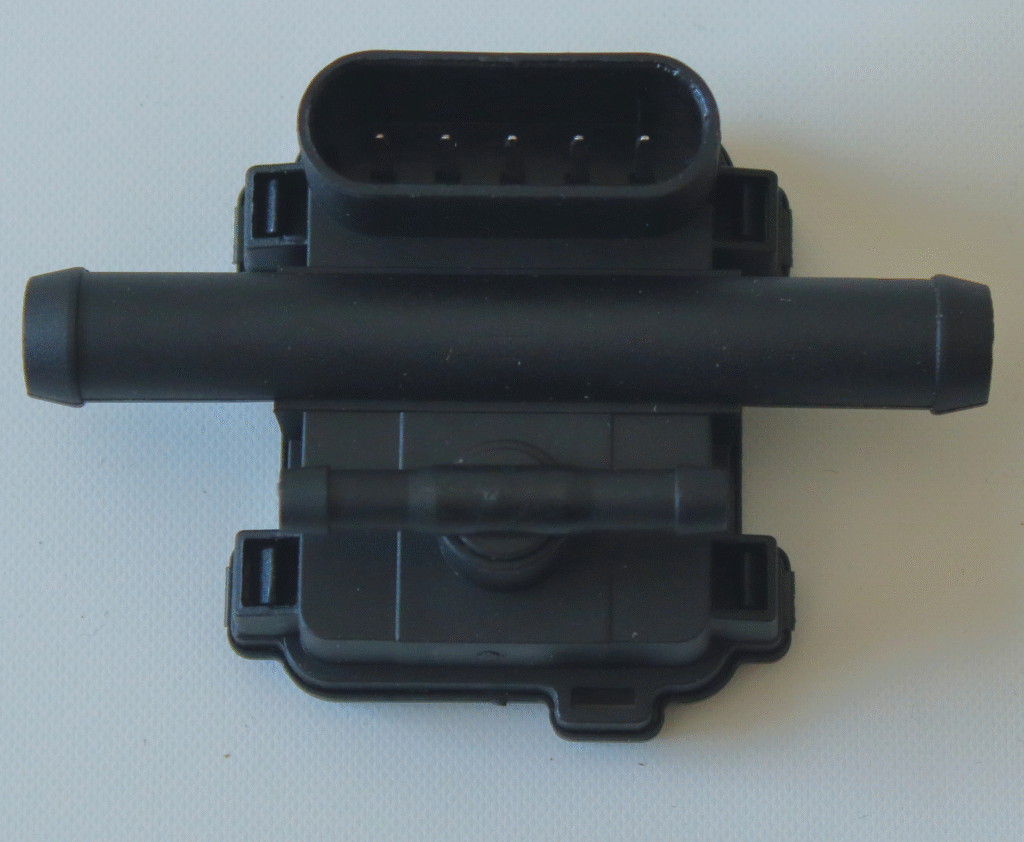

The MAP sensor is installed behind the reducer and between the gas injectors and the gas filter. The best place to mount the sensor is as close to the injectors as possible. Thanks to this, it is able to read the gas parameters just before it is applied to the machine system. On both sides, the element is connected to gas installation by gas hoses. The sensor can constantly check the parameters of the gas that flows through it.

Summary

The MAP sensor is a sensor that provides the gas installation with the necessary information regarding the pressure and the temperature of the gas. Thanks to it, the controller can control the perfect dose of gas entering the machine system, adapting the installation to a given situation. The purpose of Fuel Fusion is to maximize savings, but without exposing the engine to any risk. The MAP sensor is one of the elements that allows to achieve this goal.

Leave A Comment

You must be logged in to post a comment.